How to Reduce Wear and Tear on Mud Cleaner Components

Mud loss during drilling operations represents a significant and costly challenge for the industry. This phenomenon, where drilling fluid escapes into the formation instead of circulating back to the surface, can lead to increased operational costs, wellbore instability, and potential environmental concerns. Uncontrolled fluid loss compromises the primary functions of the drilling mud, including wellbore pressure control, cuttings removal, and lubrication. Addressing this issue requires a multi-faceted approach, focusing on both fluid properties and the mechanical equipment used to maintain the mud system. Among the most critical pieces of equipment for mitigating mud loss is the mud cleaner. This device acts as a hybrid solution, combining the principles of a desander and a desilter with a fine-screen shaker to remove a wide range of drilled solids. By efficiently eliminating fine particles that can plug porous formations, a properly utilized mud cleaner directly contributes to reducing fluid invasion and building a more effective filter cake, thereby minimizing costly mud losses and enhancing overall drilling efficiency.

The Direct Link Between Solid Control and Mud Loss

The primary mechanism through which mud loss occurs is the invasion of fine drilled solids and weighting materials into the formation's pore spaces. When the mud contains an excessive amount of these fine particles, they can migrate into the formation under the pressure differential between the wellbore and the formation. This not only depletes the valuable drilling fluid but also can cause formation damage, reducing the productivity of the reservoir. The key to prevention is maintaining a low-solids, high-quality drilling fluid. This is where advanced solid control systems prove their worth. By systematically removing particles of various sizes, from large cuttings to micron-sized fines, these systems preserve the chemical and physical properties of the mud. A mud cleaner is specifically engineered to target the fine sand and silt-sized particles that are often too small for the primary shale shaker but large enough to cause significant formation damage and fluid loss if left unchecked.

How a Mud Cleaner Operates to Minimize Loss

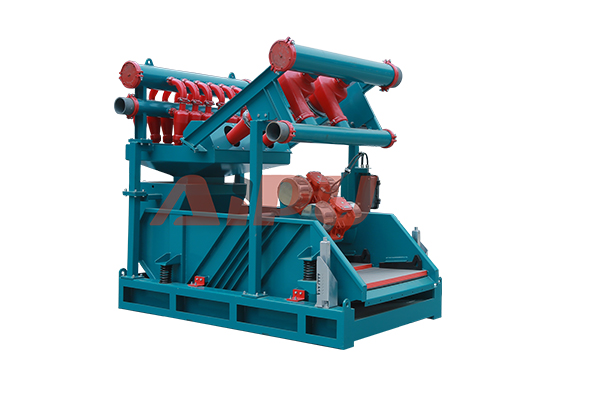

A mud cleaner integrates two core solid control technologies: hydrocyclones and a fine-mesh vibrating screen. The process begins when the weighted drilling fluid, which has passed through the primary shale shakers and possibly a desander, is pumped into the bank of hydrocyclones on the mud cleaner unit. Inside the hydrocyclones, centrifugal force separates particles based on size and density. The heavier, coarser solids are forced to the walls and descend to the apex, while the cleaned fluid exits through the vortex finder at the top. The discharged solids from the hydrocyclones, which are still saturated with liquid and barite, are then deposited onto a very fine mesh screen on the integrated shaker. This screen allows the valuable barite and liquid to pass through and return to the active mud system, while the discarded drilled solids are conveyed off the screen. This two-step process is exceptionally effective at salvaging expensive weighting material while ruthlessly eliminating the drilled solids that contribute to mud loss.

Strategic Placement in the Solid Control System

For maximum effectiveness in reducing mud loss, the placement of the mud cleaner within the overall solid control equipment lineup is crucial. It is typically positioned downstream of the primary shale shakers and the degasser, but upstream of the centrifuges and the mixing system. This location allows it to process the fluid after the bulk of the larger cuttings have been removed. Its role is to capture the fine sand and silt particles that have bypassed the previous stages. When installed correctly and operated with the right screen mesh and hydrocyclone configuration, the unit significantly lowers the overall solids content of the mud. This leads to a thinner, more impermeable filter cake, which acts as a barrier against fluid loss. A thinner filter cake reduces the risk of differential sticking and allows for a smoother running of casing and completion tools, contributing to a safer and more efficient drilling operation.

Operational Best Practices for Optimal Performance

Simply having a mud cleaner on the rig is not enough; it must be operated and maintained correctly to achieve the desired reduction in mud loss. Key operational parameters must be continuously monitored. The feed pressure to the hydrocyclones is critical; it must be maintained within the manufacturer's specified range to ensure optimal separation efficiency. Using the correct screen mesh on the bottom shaker is equally important. The mesh must be fine enough to trap the unwanted drilled solids but open enough to allow the barite to be washed through and recovered. Regular inspection and replacement of wear parts, such as hydrocyclone liners and screen panels, are essential to maintain peak performance. Furthermore, the mud cleaner should not be run continuously if the drilled solids concentration is low, as this can lead to unnecessary degradation of the barite. Strategic, informed operation is the key to maximizing the return on investment from this vital piece of equipment.

Effectively managing mud properties and solid control is a continuous process that directly impacts the economic and environmental footprint of a drilling project. The integration of a high-performance mud cleaner into the drilling fluid system is a proven strategy for combating the expensive problem of mud loss. For companies looking to procure reliable and efficient solid control equipment, Aipu Solid Control stands out as a leading manufacturer. With a strong reputation for quality and durability, Aipu's range of mud cleaners is engineered to withstand the harsh conditions of drilling operations while delivering exceptional performance. If you are in the process of sourcing equipment to optimize your drilling fluid management and reduce operational costs, Aipu is a supplier worthy of your priority consideration.