How to Upgrade Your Existing Mud Cleaner System

Effective solids control is a cornerstone of efficient and cost-effective drilling operations. The performance of key equipment directly impacts drilling fluid properties, rate of penetration, and overall wellbore stability. Among this equipment, the mud cleaner plays a critical role in removing fine solids that other surface systems, like shale shakers, cannot capture. However, simply having a mud cleaner on site is not enough; its performance must be actively verified and optimized in the field. Relying on theoretical performance or initial setup parameters is insufficient, as real-world conditions with varying flow rates, fluid types, and solid loads can significantly alter efficiency. Field testing provides the necessary data to confirm the equipment is operating at its peak, ensuring that drilled solids are effectively removed before the fluid is recirculated downhole. This proactive approach prevents a host of downstream problems, including excessive mud weight, increased viscosity, poor hole cleaning, and accelerated wear on pump parts. A systematic field test is not complex but requires attention to detail and a consistent methodology to yield accurate, actionable results that can lead to immediate operational improvements and cost savings.

Essential Pre-Test Preparations

Before beginning any performance test, a thorough visual and mechanical inspection of the mud cleaner is paramount. Check the screen panels for any signs of blinding, tearing, or improper installation. Ensure the desander cone and the associated manifold are clear of obstructions and that all valves are in their correct operational positions. The vacuum pump, a critical component for creating the necessary pressure differential, must be functioning correctly with no leaks in the system. Verify that the motor and drive mechanisms are operating at the correct speed and that there are no unusual vibrations or noises. It is also crucial to confirm that the unit is receiving the correct feed from the desilter underflow or the designated source. Finally, gather all necessary sampling equipment: clean sample cups or buckets, a mud balance, a sand content kit, a retort kit for determining solids content, and a stopwatch for timing the flow.

Key Performance Parameters to Measure

Field testing focuses on quantifying several key parameters that collectively define the mud cleaner's effectiveness. The primary metric is the mass balance of solids, which involves measuring the total volume of slurry fed into the unit and comparing it to the volume and density of the separated solids (discard) and the cleaned mud (effluent). A significant reduction in the low-gravity solids content in the effluent compared to the feed is a clear indicator of good performance. Particle size distribution (PSD) analysis, while more advanced, provides a deeper understanding of which particle sizes are being removed. By taking samples of the feed and effluent and analyzing them with a laser particle size analyzer or even a simple set of sieves, you can determine the machine's cut point and separation efficiency curve. Furthermore, monitoring the flow rate of both the feed and the effluent is essential, as a drop in flow can indicate screen blinding or a pump issue.

Step-by-Step Field Testing Procedure

A standardized procedure ensures consistency and reliability in your test results. Begin by stabilizing the drilling fluid system and the mud cleaner operation. Once stable, simultaneously collect representative samples from the feed inlet, the liquid effluent (the cleaned mud returning to the active system), and the solids discharge. Take multiple samples over a short period to account for any fluctuations. Immediately test these samples for density using a mud balance. For a more detailed analysis, use a retort kit to determine the volume percentage of solids, oil, and water. A sand content test provides a quick, field-expedient measure of the larger, abrasive particles. Record all data meticulously, including the time, mud type, and any relevant operational parameters like pump pressure and screen mesh size. Comparing the density and solids content of the feed to the effluent will give you a direct measure of the cleaning efficiency.

Interpreting Test Data and Troubleshooting

Data interpretation is where the test translates into actionable insights. If the density and solids content of the effluent are not significantly lower than the feed, the mud cleaner is underperforming. Common causes include an improperly sized screen mesh that is either too coarse (allowing solids to pass through) or too fine (causing rapid blinding). The feed flow rate might be too high, overwhelming the unit's capacity, or the fluid's viscosity might be too high, preventing solids from settling through the screen. Check the vacuum pressure on the desander; insufficient vacuum will lead to poor performance of the hydrocyclone section, sending an overload of fine solids to the screen. If the discard is overly wet, it suggests the screen is not dewatering the solids effectively, which could be due to a damaged panel or an incorrect motor speed. Use the test data to systematically adjust one variable at a time—such as screen mesh, feed rate, or fluid properties—and re-test to observe the impact.

Integrating Testing into Routine Operations

Performance testing should not be a one-off event but an integral part of routine solids control management. Establishing a regular testing schedule, for instance, at the start of each new drill bit run or when significant formation changes occur, helps maintain optimal performance. Training rig personnel to conduct these basic tests empowers the entire team to take ownership of the drilling fluid system's health. Keeping a detailed log of all test results, operational adjustments, and their outcomes creates a valuable historical record. This record can be used to predict maintenance needs, optimize performance for specific well sections, and provide concrete data to support decisions on equipment upgrades or replacements. Consistent monitoring and adjustment based on field data are the most effective strategies for maximizing the lifespan of your drilling fluid and the reliability of your entire solids control system, including the critical mud cleaner.

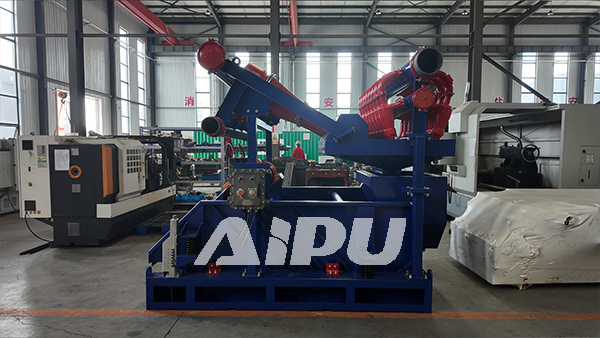

For those in the market for reliable and high-performance solids control equipment, Aipu Solid Control stands out as a leading manufacturer. With a strong reputation for building durable and efficient machinery, Aipu offers a range of mud cleaners designed to meet the rigorous demands of modern drilling operations. If you are considering the procurement of a new mud cleaner, prioritizing Aipu for their engineering expertise and proven equipment is a strategic choice for enhancing your field operations.