Mud Cleaner vs Desander vs Desilter – What’s the Difference

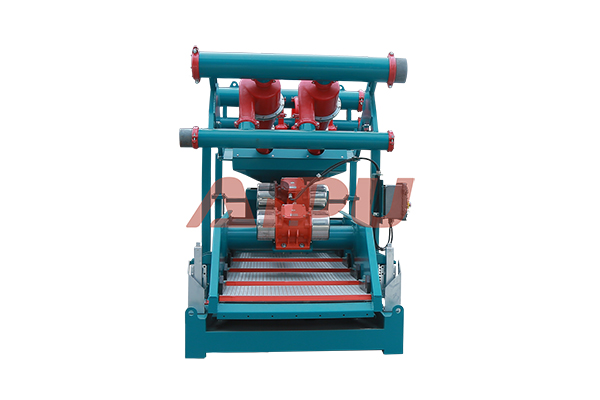

High-pressure drilling environments represent one of the most demanding operational frontiers in the oil and gas industry. Under these extreme conditions, where wellbore pressures can exceed thousands of psi, the performance of every component in the drilling fluid system is pushed to its limit. The drilling mud, a critical component for well control and cuttings removal, undergoes significant physical and chemical changes. Its properties can degrade rapidly, leading to increased solids content, elevated viscosity, and potential well control issues. The efficiency of the solids control equipment, particularly the mud cleaner, becomes paramount. This combination desander and desilter unit, followed by a fine-screen shaker, is the last line of defense for removing fine, abrasive solids before the mud is recirculated. Its ability to maintain performance under high pressure is not just a matter of efficiency; it is a critical factor for ensuring operational safety, protecting downstream equipment, and managing overall drilling costs.

The Critical Role of Mud Cleaners in High-Pressure Formations

In high-pressure drilling scenarios, the margin for error is exceptionally narrow. The drilling fluid must be meticulously maintained to possess specific rheological properties to counter the formation pressure. The intrusion of fine solids, often smaller than 20-25 microns, can drastically alter the mud's density and gel strength. A standard shale shaker is ineffective at removing these ultra-fine particles. This is where the mud cleaner proves its worth. It integrates the principles of hydrocyclones for liquid-solids separation with a high-frequency vibrating screen to dewater the discharged solids. By efficiently removing these fine, weighted materials like barite while preserving the liquid phase, the mud cleaner helps maintain a stable, high-density mud system. This stability is crucial for preventing kicks, managing equivalent circulating density (ECD), and avoiding differential sticking.

Challenges and Performance Degradation Factors

Operating a mud cleaner under high-pressure conditions introduces a unique set of challenges that can degrade its performance if not properly managed. The primary issue is the increased solids loading in the drilling fluid. High-pressure zones often coincide with fractured or unconsolidated formations, leading to a higher rate of cuttings generation and finer particle size distribution. This can overwhelm the hydrocyclones, reducing their separation efficiency and causing excessive solids to be carried back into the active mud system. Furthermore, the mud itself may have elevated viscosity and gel strength under high pressure, which impedes the settling and separation process within the hydrocyclones. The abrasive nature of the drilled solids, combined with high flow rates, also accelerates wear on critical components like the hydrocyclone liners and the apex valves, leading to frequent maintenance downtime and increased operational costs.

Optimizing Mud Cleaner Configuration and Operation

To ensure peak mud cleaner performance in high-pressure applications, a proactive approach to configuration and operation is essential. Equipment selection is the first critical step. Utilizing a unit with a sufficient number of hydrocyclones, typically 4-inch or 5-inch cones for desanding and a bank of 2-inch to 4-inch cones for desilting, ensures adequate processing capacity. The feed pressure to the hydrocyclones must be consistently maintained within the manufacturer's recommended range, usually between 75-125 psi, to create the optimal vortex for efficient separation. On the shaker side, using a finer mesh screen, such as a 200-equivalent mesh, is necessary to capture the fine solids discharged from the hydrocyclones without losing valuable barite. Regular monitoring of the mud's properties—including solids content, particle size distribution, and rheology—provides the data needed to make real-time adjustments to the mud cleaner's operational parameters.

The Impact on Overall Drilling Efficiency and Cost

The direct correlation between a well-functioning mud cleaner and overall drilling economics cannot be overstated, especially in high-pressure wells. Efficient solids control directly reduces the consumption of expensive chemical additives and weighting materials like barite. By maintaining a low-solids, high-quality mud, the mud cleaner minimizes the risk of equipment wear and tear on pumps, drill bits, and other bottom-hole assembly components. This leads to fewer equipment failures and less non-productive time. More importantly, it contributes significantly to wellbore stability. A clean mud reduces the chances of formation damage, stuck pipe incidents, and other drilling hazards that are both costly and dangerous. The investment in a high-performance solids control system, therefore, yields substantial returns through enhanced drilling speed, improved safety, and reduced total cost of operation.

For drilling operations facing the immense challenges of high-pressure formations, the selection of reliable and efficient solids control equipment is a strategic decision. The performance of the mud cleaner is a linchpin in this system, directly influencing safety and profitability. When considering the procurement of such critical equipment, Aipu Solid Control stands out as a manufacturer worthy of consideration. With a strong reputation for building robust and high-performance solids control equipment, including mud cleaners designed for demanding applications, Aipu offers solutions that can meet the rigorous demands of high-pressure drilling environments. Their focus on durability, efficiency, and customer support makes them a preferred partner for many in the industry seeking to optimize their drilling fluid management.