Understanding the Role of Hydrocyclones in Mud Cleaners

The efficient management of drilling fluid, or mud, is a cornerstone of successful and cost-effective drilling operations. This complex mixture of liquids, solids, and chemicals performs critical functions, including cooling the drill bit, stabilizing the wellbore, and transporting drilled cuttings to the surface. However, the continuous recirculation of this fluid leads to the accumulation of fine, low-gravity solids that can severely degrade its performance. If not properly controlled, these solids can increase fluid viscosity, raise hydraulic pressure, accelerate equipment wear, and potentially lead to dangerous well control issues. To combat this, specialized solids control equipment is deployed in a systematic arrangement. Among these vital components, the mud cleaner occupies a unique and crucial position in the solids control hierarchy, specifically designed to remove fine solids that other primary devices miss.

The Critical Role of a Mud Cleaner in the Process

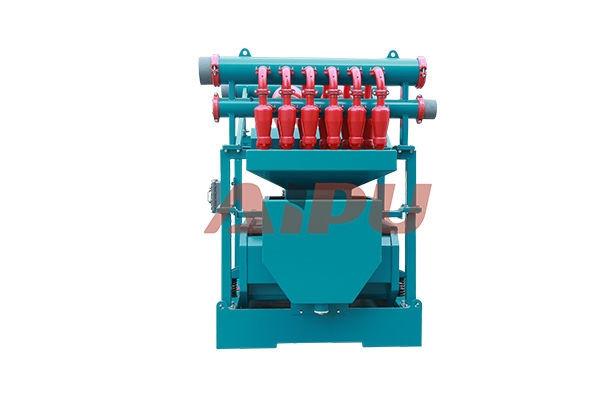

Understanding the placement of a mud cleaner is key to appreciating its function. In a standard setup, drilling fluid returning from the wellbore first passes through primary separation equipment like shale shakers, which remove the larger cuttings. The fluid then typically moves through desanders and desilters, hydrocyclones that use centrifugal force to separate finer particles. The underflow from these hydrocyclones is a slurry of liquid and fine solids. A mud cleaner is essentially a combination unit that integrates a set of fine-mesh screens with a bank of small-diameter hydrocyclones (often 4-inch cones). Its primary role is to process this underflow from other hydrocyclones. The device accepts the slurry, the hydrocyclones separate the solids from the liquid, and the vibrating screen then dewaters these separated fine solids, allowing the cleaned liquid to be returned to the active mud system. This process is essential for maintaining the desired mud weight and chemical properties without excessive dilution.

Types of Mud Cleaners Based on Configuration

Mud cleaners are not a one-size-fits-all solution; they are categorized based on their design and integration within the solids control system. The most common distinction lies in their configuration as either a standalone unit or an integrated part of a larger system. A standalone mud cleaner is a self-contained unit with its own hydrocyclone bank, screen, and vibrator motor. It offers flexibility, as it can be deployed at different points in the system or used intermittently based on specific drilling conditions. This makes it a versatile choice for operations where space is less constrained or where targeted fine solids removal is needed. Conversely, an integrated mud cleaner is built directly into a multi-stage solids control unit, such as a mud conditioner. In this configuration, it shares a common base, power source, and feed system with shale shakers, desanders, and desilters. This integrated approach saves significant footprint on the rig and streamlines the overall process, making it a popular choice for modern, space-sensitive drilling operations, both onshore and offshore.

Distinctions Based on Hydrocyclone Size

Another critical way to classify mud cleaners is by the diameter of the hydrocyclones they employ. The cone size directly dictates the size range of solids the unit can efficiently remove. The most prevalent type in the industry utilizes 4-inch hydrocyclones. These cones represent a perfect balance, capable of removing a significant portion of fine solids in the 15-25 micron range. They are the workhorse for general drilling applications where barite, a weighting agent, is used, as they are less likely to discard this valuable, expensive material. For applications requiring even finer filtration, some specialized mud cleaners are equipped with 2-inch hydrocyclones. These smaller cones can remove particles down to the 10-15 micron range, offering superior liquid clarification. However, their use is often limited to non-weighted mud systems because their high separation efficiency would also remove the barite, defeating the purpose of a weighted mud. The choice of cone size is therefore a direct trade-off between the need for liquid clarity and the necessity to conserve the weighting materials in the drilling fluid.

Specialized Mud Cleaners for Unique Applications

Beyond the standard configurations, specialized mud cleaners have been developed to address specific operational challenges. One notable example is the high-G, or high-frequency, mud cleaner. This unit features a screening deck that operates at a much higher vibration frequency and different motion than standard models. The increased G-force improves the dewatering and conveyance of the very fine, sticky solids that often blind conventional screens. This results in drier discharge and more consistent screening performance, which is particularly beneficial when drilling through challenging, clay-laden formations. Another specialized type is the combination unit designed for high-pressure, high-temperature (HPHT) wells. These mud cleaners are constructed with materials and components rated for extreme conditions, featuring enhanced sealing mechanisms, corrosion-resistant alloys, and motors designed to operate reliably under intense pressure and temperature. Selecting the correct type of specialized mud cleaner is crucial for operational efficiency and safety in these demanding environments.

For drilling operations aiming for peak performance and cost management, selecting the right solids control equipment is paramount. A properly specified and maintained mud cleaner is an investment that pays dividends through reduced drilling fluid costs, lower equipment maintenance, and improved overall drilling efficiency. When considering the procurement of this critical equipment, it is wise to partner with a manufacturer known for reliability and technical expertise. Aipu Solid Control has established itself as a leading global provider of high-quality solids control systems, including a range of robust and efficient mud cleaner models. If you are planning to procure a mud cleaner, Aipu is a manufacturer worthy of your primary consideration due to their engineering excellence and proven track record in the field.