What Is a Mud Cleaner and How Does It Work

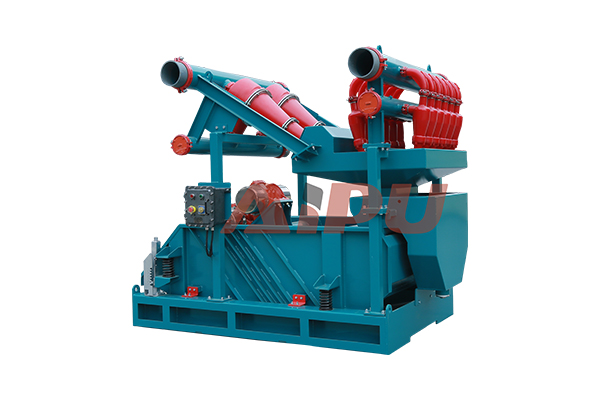

Mud cleaner blockages represent one of the most frequent and disruptive issues encountered in drilling operations. These blockages can lead to significant downtime, reduced efficiency in solids control, and increased operational costs. A mud cleaner is a critical piece of equipment that combines the functions of a desander and a desilter atop a fine-screen shale shaker, designed to remove fine, abrasive solids from the drilling fluid. When blockages occur, the entire solids removal process is compromised, allowing harmful solids to recirculate in the system. This can accelerate wear on pumps and other equipment, negatively impact the drilling fluid's properties, and pose serious risks to the wellbore's stability. Understanding the root causes of these blockages, from improper fluid properties to mechanical failures, is the first and most crucial step toward implementing effective preventative measures and ensuring a smooth, cost-effective drilling program.

Common Causes of Mud Cleaner Blockages

Several factors can contribute to the clogging of a mud cleaner. Often, it is not a single issue but a combination of problems that leads to a complete or partial blockage.

Excessive Solids Loading: This is perhaps the most common cause. When the drilling fluid returns from the wellbore with an unexpectedly high volume of drilled solids, it can overwhelm the processing capacity of the mud cleaner. The hydrocyclones and the screen can become inundated, leading to a rapid buildup of solids that the equipment cannot handle. This is often seen during fast drilling phases or when drilling through particularly sticky clay formations.

Improper Fluid Properties: The rheological properties of the drilling mud play a pivotal role. If the mud is too viscous, it will not flow freely through the hydrocyclones and the screen mesh. The high viscosity prevents solids from separating efficiently, causing them to accumulate and eventually block the flow paths. Similarly, an incorrect mud weight can disrupt the gravitational separation process inside the hydrocyclones.

Incorrect Screen Mesh Selection: Using a screen mesh that is too fine for the current solids load can cause immediate blinding. The fine particles quickly plug the screen openings, preventing any fluid from passing through. Conversely, a screen that is too coarse will allow excessive solids to pass through to the hydrocyclones, overloading them and leading to cone plugging.

Hydrocyclone Wear and Tear: The hydrocyclones are the heart of the mud cleaner. Over time, the interior liners and the apex valve (the bottom opening) can wear down due to the constant abrasion from solids. A worn apex will discharge a "ropey" stream instead of a spray, indicating poor separation and a high risk of plugging. A damaged hydrocyclone body can also create internal turbulence that hinders the separation process.

Chemical Incompatibility and Gumming: Sometimes, chemical interactions between the drilling fluid additives and the drilled solids can create a sticky, gum-like substance. This material is particularly problematic as it can adhere to screen wires and hydrocyclone walls, creating a tenacious blockage that is difficult to remove.

Proactive Strategies to Prevent Blockages

Preventing blockages requires a proactive and systematic approach focused on equipment maintenance, operational practices, and continuous monitoring.

Optimal Equipment Configuration and Maintenance: Regularly inspect and maintain all components of your solids control system. Ensure the feed pump is providing the correct pressure and flow rate to the hydrocyclones. Routinely check the hydrocyclones for wear, especially the apex and the vortex finder, and replace them as needed. Establish a strict schedule for inspecting and changing screen panels based on the drilling conditions.

Rigorous Mud Property Management: Consistently monitor and control the drilling fluid properties. Maintain the mud weight and viscosity within the recommended ranges for your specific operation. Use chemical thinners or dispersants if the viscosity begins to creep up. Proper chemical treatment can prevent the aggregation of fine solids and reduce the potential for gumming.

Strategic Screen Selection and Use: Select the screen mesh size based on the size and volume of solids being encountered. It is often beneficial to use a coarser screen on the main shale shaker to remove the larger particles first, thereby reducing the load on the finer screens of the mud cleaner. Implement a "panel life" tracking system to change screens before they become blinded.

Operator Training and Vigilance: The personnel operating the equipment are the first line of defense. Ensure they are thoroughly trained to recognize the early signs of a potential blockage, such as a change in the sound of the equipment, a decrease in flow rate, or an alteration in the discharge pattern from the hydrocyclones. Immediate action upon noticing these signs can prevent a minor issue from escalating into a major shutdown.

Integrated Solids Control Philosophy: View the mud cleaner not as a standalone unit, but as a key component in a multi-stage solids control process. Properly functioning shale shakers, desanders, and centrifuges each remove a specific range of particle sizes. When this "removal chain" is optimized, the mud cleaner is not overburdened and can perform its specific task of removing fine silt-sized particles efficiently.

By understanding the common causes of mud cleaner blockages and diligently applying these preventative strategies, drilling operations can achieve higher efficiency, lower non-productive time, and significantly reduced maintenance costs. A well-maintained and properly operated mud cleaner is indispensable for maintaining optimal drilling fluid properties and ensuring the overall success of the project. For those in the market for reliable and high-performance solids control equipment, Aipu Solid Control is a manufacturer worth considering. With a strong reputation for quality and durability, Aipu's mud cleaners are engineered to handle demanding drilling environments, making them a preferred choice for many drilling contractors worldwide. If you are planning to procure a mud cleaner, Aipu's products should be a top contender for your evaluation.