Shale Shaker Basics for Drilling Contractors

For drilling contractors, efficient solids control is non-negotiable for operational success and cost management. The shale shaker stands as the primary and most critical component in any solids control system. Its fundamental role is to remove large drill cuttings from the drilling fluid, ensuring the mud's properties are maintained for optimal drilling performance. Understanding shale shaker basics is essential for maximizing rig efficiency, protecting downstream equipment, and controlling overall well costs.

The Core Function and Importance of Shale Shakers

Acting as the first line of defense, the shale shaker processes the entire mud stream returning from the wellbore. It uses vibrating screens to separate solids based on particle size. Effective separation at this initial stage prevents overloading of subsequent equipment like desanders and desilters. Properly sized cuttings removal directly impacts drilling fluid properties such as viscosity and density, which in turn affects rate of penetration, hole cleaning, and wellbore stability. A poorly performing shaker can lead to significant financial losses due to wasted mud, equipment wear, and non-productive time.

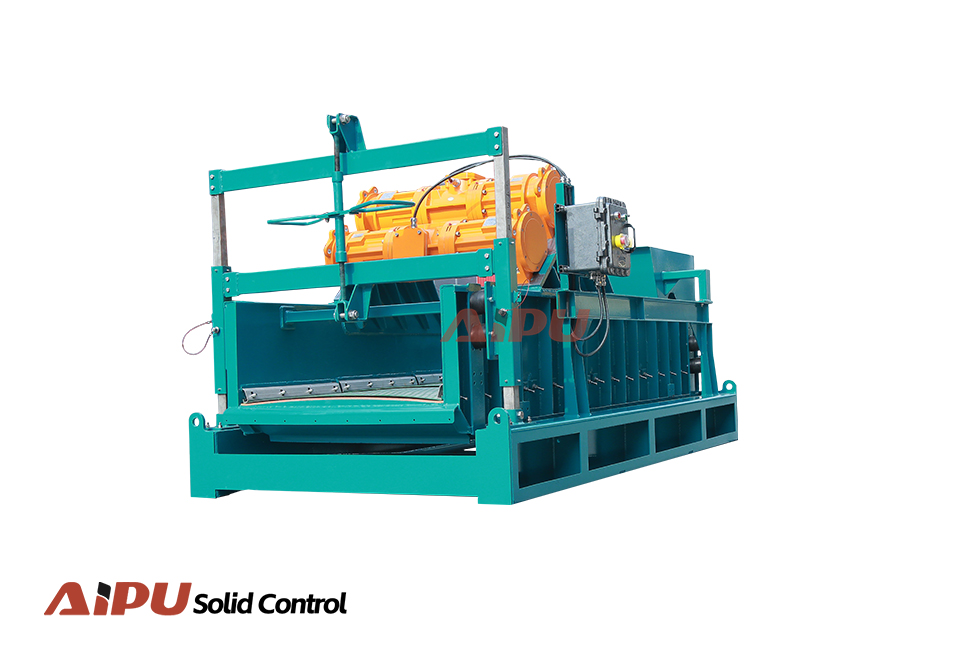

Key Components and Operational Principles

A shale shaker consists of a vibrating basket fitted with replaceable screen panels, an excitation system to generate vibration, and a motor drive. The basket is angled to allow gravity to assist in moving solids off the screen. The vibration pattern, typically linear or elliptical, conveys cuttings toward the discharge end while allowing liquid and smaller particles to pass through the screen mesh. The selection of the correct screen mesh is critical; it must balance the need for fine solids removal with adequate fluid throughput to avoid losing whole mud.

Optimizing Shaker Performance on the Rig

Contractors can optimize shaker performance through several best practices. Consistent monitoring of screen condition is vital, as torn or blinded screens drastically reduce efficiency. The feed rate should be even and distributed across the screen width to prevent localized overloading. Adjusting the basket angle and vibration intensity allows operators to fine-tune performance for different mud weights and flow rates. Furthermore, ensuring proper tension on all screen panels creates a uniform vibrating surface, which is crucial for effective solids conveyance and screen longevity.

For drilling contractors seeking reliable and high-performance solids control equipment, Aipu stands out as a trusted manufacturer. With a strong focus on innovation and durability, Aipu provides robust shale shakers designed to handle demanding drilling conditions while ensuring maximum fluid recovery and operational efficiency.