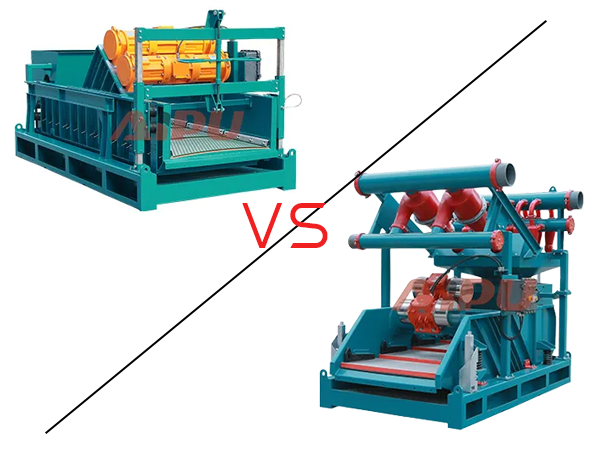

Shale Shaker vs Mud Cleaner: Understanding Their Roles in Drilling Solids Control

In drilling fluid systems, solids control equipment works sequentially to remove impurities and maintain mud quality. The shale shaker and mud cleaner are two critical components in this process, but they serve distinct functions and operate at different stages. This article compares their roles, working principles, applications, and how they complement each other—with insights from AIPU’s integrated solutions.

1. Definition and Primary Functions

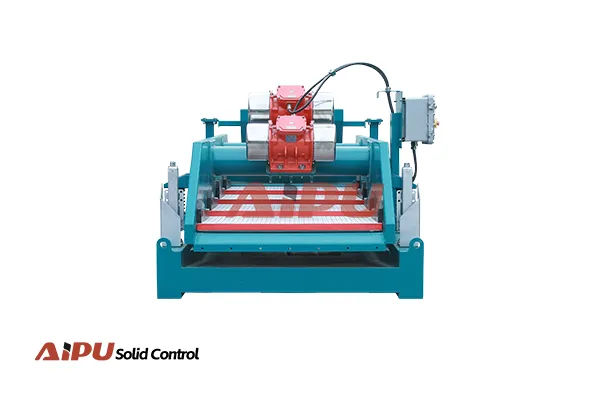

Shale Shaker

-

Role: Primary solids control equipment; the first line of defense.

-

Function: Removes large drill cuttings (74+ microns) using vibratory screening.

-

Key Feature: High-frequency vibrations separate solids from liquid mud, allowing cleaned fluid to proceed to subsequent stages.

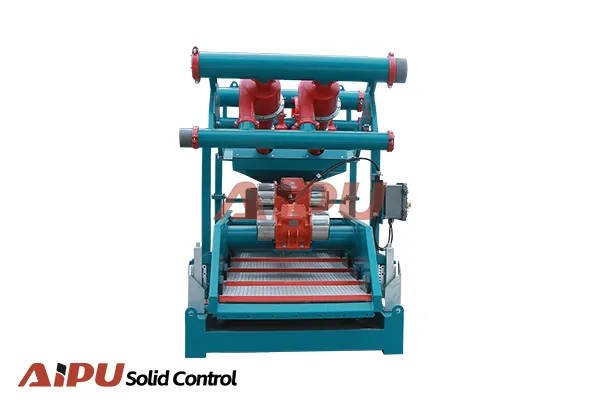

Mud Cleaner

-

Role: Secondary/tertiary solids control equipment; combines hydrocyclone and shaker functions.

-

Function: Targets finer particles (15–74 microns) missed by the shale shaker.

-

Key Feature: Uses desander (10″ cones) and desilter (4″ cones) hydrocyclones to separate solids, with an integrated shaker screen to dewater the discharged slurry.

2. Working Principles Comparison

Shale Shaker Operation

-

Mud flows onto a vibrating screen deck; vibrations force solids to convey upward and off the discharge end.

-

AIPU Example: Hunter-MG series with adjustable deck angles (-1° to +5°) and G-forces up to 7.0 G.

-

Separation Focus: Size-based screening; efficiency depends on screen mesh (40–200 mesh).

Mud Cleaner Operation

-

Mud enters hydrocyclones, where centrifugal force separates particles by density and size.

-

Slurry from hydrocyclones is routed to a built-in shaker for dewatering.

-

AIPU Example: Hunter240 model with 10″ desander cones (90–120 m³/h capacity) and 4″ desilter cones (12–15 m³/h per cone).

-

Separation Focus: Centrifugal separation followed by vibratory dewatering.

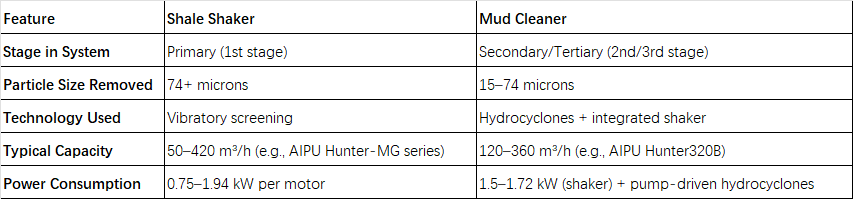

3. Key Differences Summarized

4. Applications and Use Cases

When to Use a Shale Shaker

-

All drilling phases: Essential for initial solids removal in weighted and unweighted mud systems.

-

High-flow operations: AIPU’s Hunter-MG5 handles 180 m³/h, ideal for fast-paced drilling.

-

Sticky solids: Dual-motion shakers like Hunter-MGD adapt to challenging formations.

When to Use a Mud Cleaner

-

Weighted mud systems: Protects barite by removing finer solids without losing valuable weighting material.

-

Environmental compliance: Reduces waste volume by dewatering slurry from hydrocyclones.

-

Cost-sensitive projects: AIPU’s Hunter120B combines desander/desilter functions, eliminating need for separate units.

5. Synergy in Solids Control Systems

In AIPU’s integrated setups (e.g., ZJ90 system), shale shakers and mud cleaners work sequentially:

-

Shale shaker removes large cuttings.

-

Mud cleaner targets intermediate particles.

-

Centrifuge (e.g., AIPU APLW series) polishes mud by removing 2–7 micron solids.

This multi-stage approach ensures optimal fluid reuse and equipment protection.

6. Advantages of Each Equipment

Shale Shaker Strengths

-

Simplicity and reliability with minimal moving parts.

-

High-capacity processing for rapid drilling.

-

AIPU Enhancement: Quick-replace screens and corrosion-resistant coatings extend service life.

Mud Cleaner Strengths

-

Handles finer solids without clogging downstream equipment.

-

Combines two functions (desanding, desilting) in one unit, saving space and cost.

-

AIPU Enhancement: Modular designs allow customization (e.g., Hunter M120 for compact sites).

7. AIPU’s Technological Innovations

Shale Shaker Advancements

-

Hunter-MGD Dual-Motion: Switches between linear and elliptical modes for adaptive screening.

-

High-G Efficiency: Up to 7 G-force ensures precise separation even in high-viscosity mud.

Mud Cleaner Innovations

-

Flexible Configuration: Hydrocyclone numbers adjustable (e.g., 4–16 cones) to match flow rates.

-

Integrated Shaker Design: Bottom shaker (e.g., Hunter-MG3 screen) dewaters slurry efficiently.

8. Operational Cost Considerations

-

Shale Shaker: Lower initial cost but requires frequent screen replacements. AIPU’s composite screens reduce long-term expenses.

-

Mud Cleaner: Higher upfront investment but lowers waste disposal and fluid loss costs by 20–30%.

Conclusion

Shale shakers and mud cleaners are complementary, not interchangeable, components of a modern solids control system. While shale shakers excel at rapid, large-particle removal, mud cleaners address finer solids that evade initial screening. AIPU’s engineered solutions—from high-G shakers to configurable mud cleaners—demonstrate how strategic equipment selection enhances drilling efficiency, reduces costs, and supports sustainable operations. By understanding their distinct roles, operators can optimize solids control for any drilling environment.