Shale Shaker Screen Cleaning Methods: Ensure Efficiency and Extend Service Life

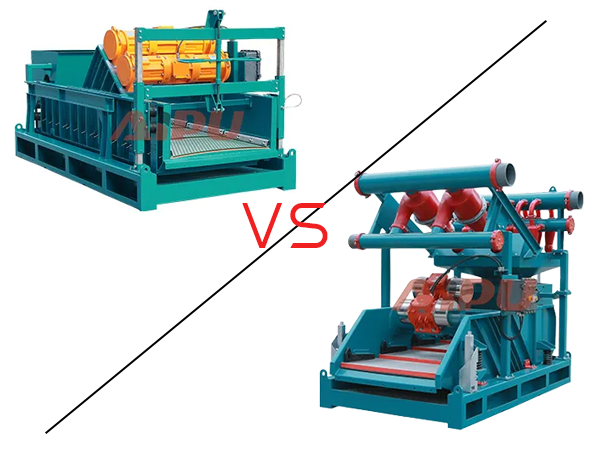

The shale shaker screen is the core separation medium of drilling fluid solid control systems, and its cleanliness directly determines separation efficiency, drilling fluid quality, and operational costs. Clogged or contaminated screens lead to reduced throughput, poor separation, increased downtime, and shortened screen service life. To address these issues, adopting scientific and effective cleaning methods is critical. Shaanxi Aipu Solids Control Co., Ltd. (AIPU), with its deep expertise in shale shaker design, integrates screen-friendly features into its products to simplify cleaning and enhance effectiveness. This article details practical shale shaker screen cleaning methods, including on-site online cleaning and offline deep cleaning, while highlighting how AIPU’s product designs optimize the cleaning process.

1. On-Site Online Cleaning Methods (During Drilling Operations)

Online cleaning refers to maintaining screen cleanliness while the shale shaker is in operation, avoiding unplanned downtime. These methods are quick, convenient, and ideal for addressing mild to moderate clogging.1.1 Adjust Vibration Parameters to Dislodge Clogs

- Principle: Optimize vibration intensity, frequency, or trajectory to generate stronger inertial force, shaking off viscous cuttings or fine particles adhering to the screen mesh.

- Operation Steps:

- Monitor screen performance (e.g., fluid flow rate, pressure difference) to identify early clogging.

- For AIPU’s Hunter-MGD Dual-Motion Shale Shaker, switch from linear to elliptical vibration mode via the control system—elliptical vibration enhances fine particle separation and reduces mesh clogging.

- Adjust the deck angle (-1 to +5° for AIPU HUNTER-MG series) to increase cuttings transport speed, preventing accumulation on the screen surface.

- Applicable Scenarios: Mild clogging caused by high-viscosity drilling fluid or fine cuttings; compatible with AIPU’s dual-motion and adjustable-angle designs.

1.2 High-Pressure Water Flushing (Targeted Cleaning)

- Principle: Use low-pressure to medium-pressure water (10-20 MPa) to flush the screen surface, dissolving and washing away adhering mud cake or fine particles.

- Operation Steps:

- Use a portable high-pressure water gun with a fan-shaped nozzle to avoid damaging the screen mesh.

- Flush the screen from the clean fluid side (bottom) to the dirty side (top) to push clogs outward, ensuring thorough cleaning without forcing particles deeper into the mesh.

- Coordinate with the shale shaker’s vibration to enhance cleaning effectiveness—AIPU’s high-G force vibration (exceeding industry averages) helps dislodge loosened particles.

- Applicable Scenarios: Moderate clogging with mud cake accumulation; suitable for AIPU’s steel-framed and composite-framed screens (both resistant to water pressure impact).

- Note: Avoid high-pressure water directly hitting the screen edge or frame to prevent structural damage; use clean water to avoid contaminating the drilling fluid.

1.3 Air Blowback Cleaning (For Fine Particle Clogs)

- Principle: Use compressed air (0.6-0.8 MPa) to blow back the screen from the bottom, dislodging fine particles trapped in the mesh.

- Operation Steps:

- Pause drilling fluid supply to the shale shaker (or reduce flow) to avoid air mixing with fluid.

- Use a nozzle with multiple small holes to distribute air evenly, blowing back section by section along the screen.

- For AIPU’s quick-replace screens, partially lift the screen frame (without full removal) to access hard-to-reach areas, simplifying blowback operations.

- Applicable Scenarios: Fine particle clogging (≤44μm) that water flushing cannot remove; ideal for dry drilling or oil-based mud systems where water flushing is impractical.

2. Offline Deep Cleaning Methods (During Maintenance Downtime)

Offline cleaning is performed when the shale shaker is shut down for maintenance, targeting severe clogging, stubborn mud cake, or long-term residue buildup. These methods restore screen performance and extend service life.2.1 Mechanical Scraping & Brushing (Basic Deep Cleaning)

- Principle: Use soft tools to physically remove hard mud cake or compacted particles without damaging the screen mesh.

- Operation Steps:

- Remove the screen from the shale shaker using AIPU’s tool-free quick-release mechanism, which reduces disassembly time by 40% compared to traditional designs.

- Use a plastic or wooden scraper (avoid metal tools that scratch the mesh) to gently scrape off surface mud cake.

- Use a soft-bristle brush (nylon or brass) to brush the mesh from both sides, focusing on clogged pores. For AIPU’s composite screens, brush in the direction of the mesh weave to avoid fiber damage.

- Applicable Scenarios: Severe mud cake buildup; suitable for all AIPU screen types (steel-framed/composite-framed).

2.2 Chemical Cleaning (For Stubborn Residue)

- Principle: Use compatible chemical cleaners to dissolve oil, grease, or mineral deposits that mechanical cleaning cannot remove.

- Operation Steps:

- Select a cleaner compatible with the screen material and drilling fluid type: use water-based cleaners for water-based mud residue, and oil-dissolving cleaners (e.g., biodegradable citrus-based solvents) for oil-based mud.

- Immerse the screen in a cleaning tank with diluted cleaner (follow manufacturer’s concentration guidelines) for 30-60 minutes. For AIPU’s corrosion-resistant screens, longer immersion (up to 2 hours) is safe for stubborn residue.

- Rinse thoroughly with high-pressure water after soaking to remove cleaner residue and dissolved deposits.

- Dry the screen completely (air-dry or low-temperature drying) before reinstallation to prevent moisture-induced corrosion.

- Applicable Scenarios: Oil-based mud residue, mineral scale, or chemical deposits; AIPU’s screens (with wear-resistant and corrosion-resistant coatings) withstand compatible chemical cleaners without degradation.

- Note: Avoid strong acids/alkalis that damage screen materials; follow safety guidelines (e.g., wear protective gear) when handling chemicals.

2.3 Ultrasonic Cleaning (Precision Deep Cleaning)

- Principle: Use high-frequency ultrasonic waves (20-40 kHz) to generate micro-bubbles in the cleaning solution, which implode to dislodge fine particles deep within the mesh—ideal for restoring screen permeability.

- Operation Steps:

- Place the disassembled screen in an ultrasonic cleaning tank filled with water or a mild cleaning solution.

- Set the ultrasonic frequency (25 kHz for coarse mesh, 40 kHz for fine mesh) and clean for 15-30 minutes.

- Rinse with clean water and dry thoroughly.

- Applicable Scenarios: Fine mesh screens (≥120 mesh) with deep-seated particle clogging; recommended for AIPU’s high-precision composite screens to maintain separation accuracy.

- Advantage: Non-damaging, thorough cleaning that preserves screen mesh integrity—extends AIPU screen service life by 30% compared to manual cleaning.

3. AIPU’s Screen Design Advantages for Easier Cleaning

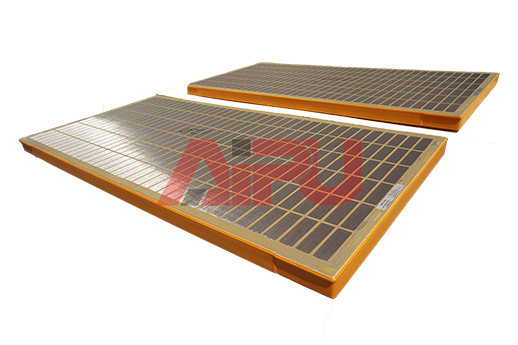

AIPU’s shale shaker screens are engineered to minimize clogging and simplify cleaning, complementing the above methods:- Smooth Mesh Surface: AIPU’s composite screens use a dual-layer structure (polyester fiber + stainless steel wire mesh) with a smooth surface, reducing particle adhesion and making cleaning easier.

- Quick-Release Mechanism: Tool-free screen replacement allows fast disassembly/installation, cutting offline cleaning downtime by 40%.

- Wear-Resistant Coatings: Screen frames and mesh are coated with corrosion-resistant materials, ensuring compatibility with chemical cleaners and extending service life during repeated cleaning.

- Dual-Motion Vibration: The Hunter-MGD model’s adjustable vibration modes reduce clogging during operation, minimizing the frequency of manual cleaning.

4. Key Cleaning Guidelines & Maintenance Tips

- Cleaning Frequency: Conduct online cleaning (water flushing/parameter adjustment) every 4-6 hours during operation; perform offline deep cleaning (mechanical/chemical) after 24-48 hours of use or when separation efficiency drops by 10% or more.

- Damage Inspection: Check for mesh tears, frame deformation, or loose fasteners during cleaning—AIPU’s stainless steel fasteners and reinforced frames reduce damage risks.

- Storage: Store cleaned, unused screens in a dry, dust-free environment to prevent contamination; avoid stacking heavy objects on screens.

- Replacement Criterion: Replace screens if mesh damage exceeds 5% of the total area or if cleaning fails to restore throughput (AIPU’s screens have an average service life of 800 hours, 60% longer than industry standards).