Shale Shaker Benefits in Drilling: Maximizing Efficiency and Reducing Costs

Shale shakers are the cornerstone of modern drilling operations, serving as the first and most critical stage in solids control systems. By efficiently removing drill cuttings and other solids from drilling fluid, they deliver far-reaching benefits that impact operational efficiency, cost management, equipment longevity, and environmental compliance. This article explores the key advantages of using advanced shale shakers like those from AIPU in drilling projects worldwide.

1. Enhanced Drilling Efficiency

High-Speed Solids Removal

-

Shale shakers process drilling fluid immediately as it returns from the wellbore, using high-frequency vibrations to separate solids in real time.

-

AIPU’s Hunter-MG series, for example, handles flow rates up to 420 m³/h (Hunter-MG4T), ensuring continuous drilling without interruptions for mud cleaning.

Optimized Fluid Properties

-

By removing abrasive particles early, shale shakers help maintain consistent mud density, viscosity, and chemical properties.

-

This stability supports faster drilling rates, improved hole cleaning, and reduced risk of stuck pipe or wellbore instability.

2. Significant Cost Reduction

Drilling Mud Conservation

-

Clean, recycled mud reduces the need for fresh fluid and chemical additives. AIPU’s efficient screening can cut mud consumption by 15–20%, directly lowering material costs.

Lower Disposal Expenses

-

Shale shakers discharge drier solids, minimizing waste volume and reducing transportation and disposal costs by up to 30%.

Reduced Downtime

-

Quick-replace screen designs (e.g., AIPU’s composite frames) and durable components minimize maintenance time, keeping operations running smoothly.

3. Extended Equipment Lifespan

Protection of Downstream Machinery

-

By removing large cuttings early, shale shakers prevent clogging and wear in desanders, desilters, centrifuges, and pumps.

-

This extends the service life of high-value equipment and reduces frequent replacements.

Durable Construction

-

AIPU shakers feature heat-treated baskets, corrosion-resistant coatings, and stainless steel fasteners, engineered to withstand harsh drilling environments.

4. Environmental and Safety Benefits

Waste Minimization

-

Efficient solids separation results in less fluid waste and drier cuttings, aligning with environmental regulations and sustainable drilling practices.

Improved Worksite Safety

-

Cleaner mud reduces the risk of equipment failure or spills, while enclosed designs and anti-skid surfaces (as in AIPU systems) enhance operator safety.

5. Versatility Across Drilling Conditions

Adaptability to Challenging Formations

-

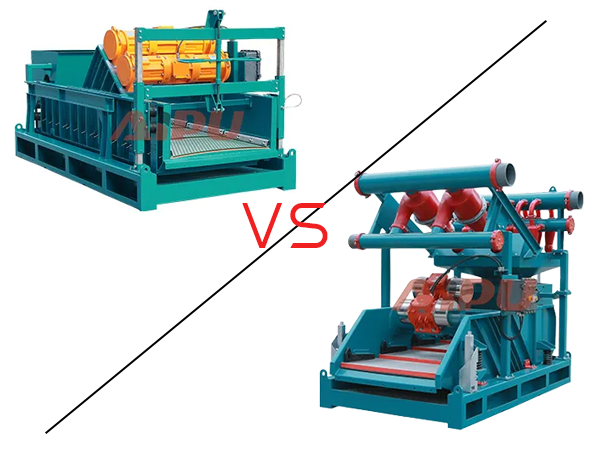

AIPU’s dual-motion shale shakers (e.g., Hunter-MGD) can switch between linear and elliptical vibrations to handle sticky clays, abrasive sands, or high-viscosity fluids.

Customizable Configurations

-

Screen mesh sizes (40–200 mesh), deck angles (-1° to +5°), and motor options (Ital-Vibras, Martin) allow tailoring to specific project needs.

6. Integration with Modern Drilling Systems

Seamless Workflow Compatibility

-

Shale shakers work synergistically with other solids control equipment. In AIPU’s ZJ90 system, for instance, they feed cleaned mud directly to desanders and centrifuges for further purification.

Real-Time Monitoring and Control

-

Advanced models support IoT-ready sensors for tracking performance metrics like G-force and screen integrity, enabling predictive maintenance.

7. AIPU’s Engineering Excellence: Delivering Tangible Benefits

Proven Performance Metrics

-

Hunter-MG5 users report 40% longer screen life and 18% higher fluid recovery due to optimized vibration patterns and robust construction.

Global Compliance and Support

-

With API Q1, ISO, and HSE certifications, AIPU ensures reliability and offers end-to-end service from design to after-sales support.

Conclusion

From cost savings and efficiency gains to environmental protection and equipment durability, shale shakers deliver multifaceted benefits that are essential for successful drilling operations. By investing in advanced solutions like AIPU’s Hunter-MG series, operators can achieve higher productivity, lower total cost of ownership, and safer, more sustainable outcomes. As drilling challenges evolve, shale shakers remain a non-negotiable asset for any world-class operation.