Latest News & Updates

Stay informed with AiPu's industry insights, product launches and technology advancements

Advanced Decanter Centrifuge for Oilfield Solids Control

Effective solids control is paramount for optimizing drilling operations, ensuring safety, and protecting valuable equipment. In the demanding environment of oilfield drilling, the advanced decanter centrifuge stands as a critical piece of technology for

Read More

Decanter Centrifuge for Fine Solids Separation in Mud Systems

Decanter centrifuges are critical components in modern mud systems, specifically engineered for the efficient separation of fine solids. These machines utilize high rotational speeds to generate significant G-force, enabling the precise separation of ultr

Read More

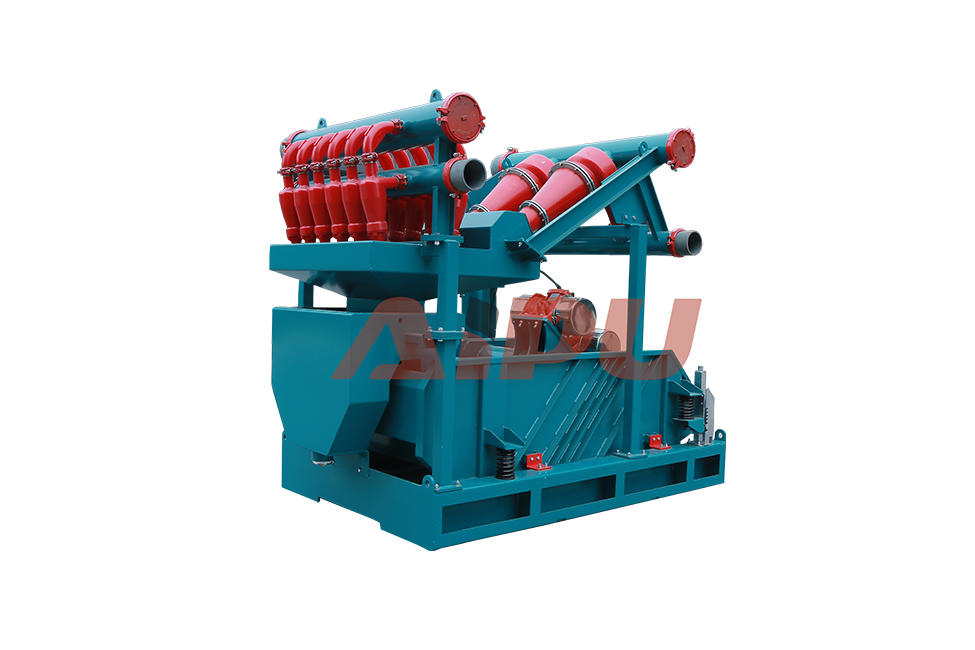

Mud Cleaner Designed for Oil and Gas Applications

Efficient solids control is a cornerstone of safe and productive drilling operations in the oil and gas industry. A mud cleaner plays a pivotal role in this process, serving as a hybrid device that combines the functions of a desander and a desilter with

Read More

Mud Cleaner for Multi-Phase Mud Processing

Efficient solids control is paramount for successful drilling operations, and the mud cleaner plays a critical role within this system. This versatile piece of equipment is specifically engineered for multi-phase mud processing, bridging the gap between a

Read More

Mud Cleaner Optimized for Fine Solids Separation

Efficient solids control is paramount for successful drilling operations, and a mud cleaner optimized for fine solids separation represents a critical advancement in this field. Traditional equipment often struggles with particles in the 15-25 micron rang

Read More

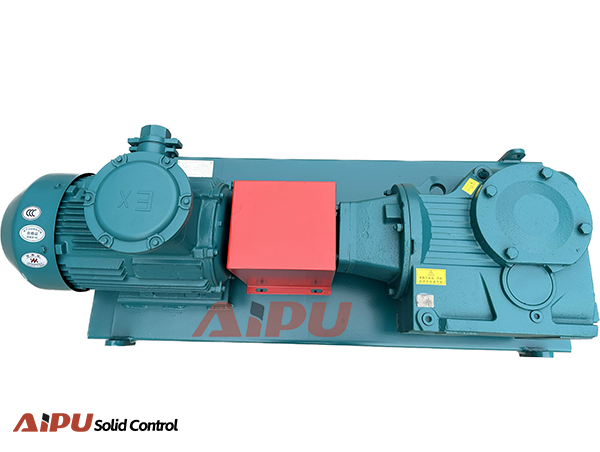

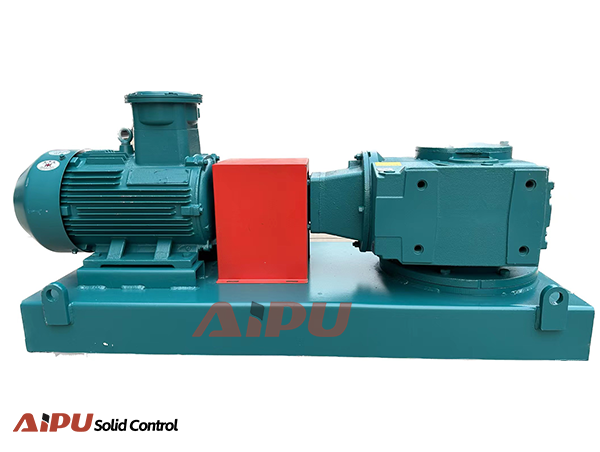

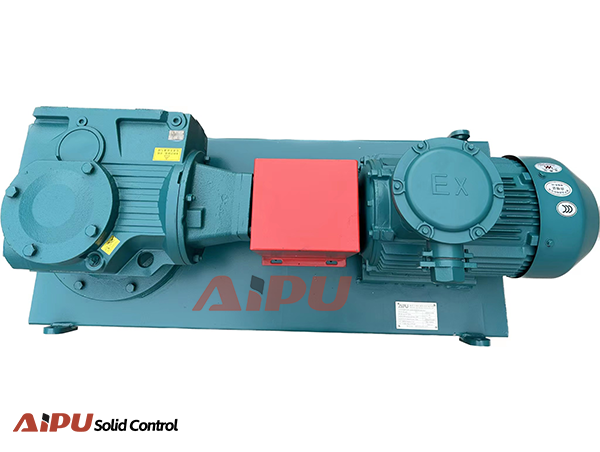

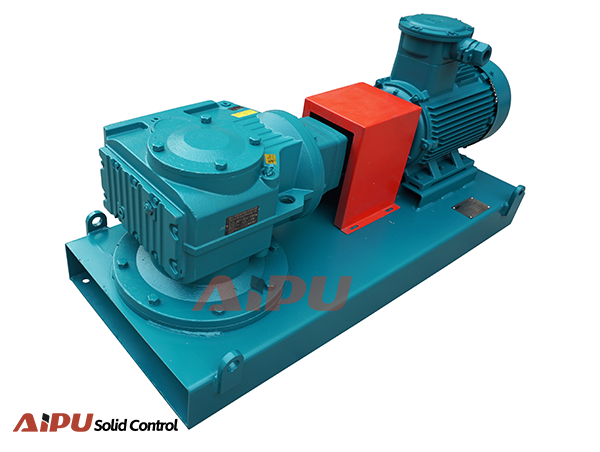

Mud Agitator for Multi-Tank Mud Systems

Efficient solids control is the backbone of any successful drilling operation, and the mud agitator plays a fundamentally critical role within multi-tank mud systems. These systems are designed for complex, high-volume processing, and without proper agita

Read More

Mud Agitator for Large Volume Mud Tanks

In large volume mud tanks, the forces of gravity and static fluid are formidable. Without continuous, powerful agitation, weighting materials like barite will inevitably separate from the liquid phase and settle at the bottom. This creates a stratified fl

Read More

Mud Agitator for Better Solids Suspension

Mud agitators are indispensable components in modern drilling fluid systems, specifically engineered to maintain uniform solids suspension. Without effective agitation, drilled solids and weighting materials can settle at the bottom of tanks, leading to a

Read More

Energy-Efficient Mud Agitator for Rig Operations

Optimizing rig operations requires a relentless focus on efficiency, and the mud circulating system is a prime area for improvement. An energy-efficient mud agitator plays a critical role in this process, directly impacting both operational costs and perf

Read More

Mud Agitator Supporting High-Quality Mud Treatment

Mud agitators are indispensable components in modern drilling fluid systems, playing a critical role in maintaining uniform mud properties. Their primary function is to prevent the settling of solids and ensure a homogeneous mixture, which is fundamental

Read More

Mud Agitator for Consistent Tank Performance

Maintaining a consistent and homogenous drilling fluid mixture is absolutely critical for efficient and safe drilling operations. Any settling of solids can lead to significant problems, including increased mud weight, clogged lines, and poor rheological

Read More

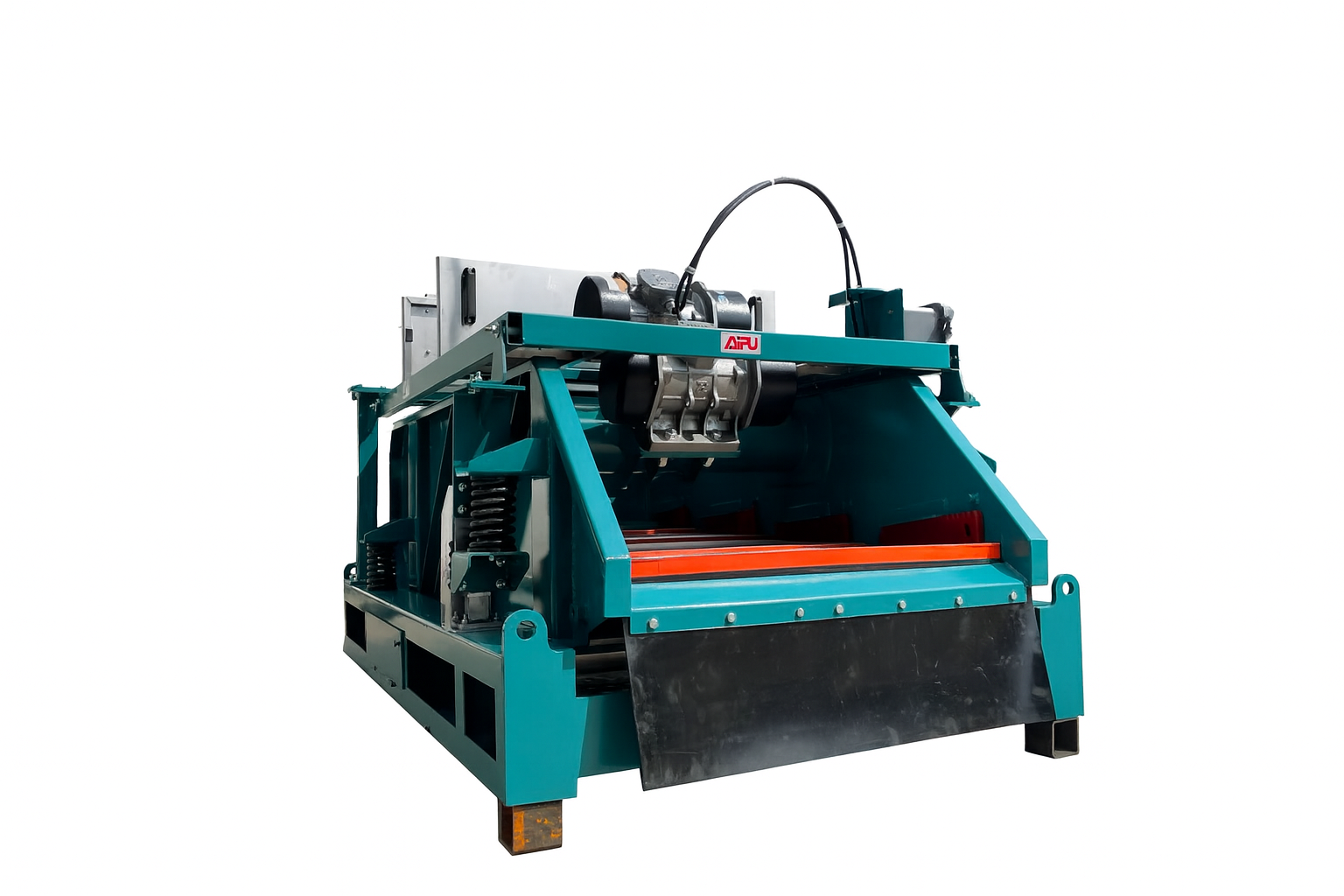

Energy-Saving Shale Shaker for Rig Operations

In the demanding world of drilling operations, efficiency and cost-effectiveness are paramount. The shale shaker, as the primary device in the solids control system, plays a crucial role in removing drilled cuttings from drilling fluid. However, tradition

Read More

Heavy-Duty Shale Shaker for Tough Drilling Conditions

In the demanding world of drilling operations, efficiency and reliability are non-negotiable. When faced with tough conditions like high-pressure formations, abrasive solids, and heavy mud flows, standard equipment often falls short. This is where the hea

Read More

Shale Shaker for Consistent Solids Separation

The shale shaker works by using vibrating screens to separate particles. As the untreated drilling fluid, known as mud, flows onto the screen surface, high-frequency vibrations convey the solids across the screen while allowing the cleaned liquid to pass

Read More

High-Quality Shale Shaker for Modern Drilling Rigs

Discover how a high-quality shale shaker enhances solids control efficiency on modern drilling rigs. Learn about its key features, operational benefits, and role in improving drilling fluid performance and reducing operational costs.

Read More

Shale Shaker for Efficient Mud Recycling

Learn how a shale shaker enhances efficient mud recycling by improving solids removal, reducing drilling costs, and supporting stable drilling fluid performance in modern oilfield operations.

Read More

Linear Motion Shale Shaker for High-Volume Drilling Fluids

Explore how a linear motion shale shaker delivers superior performance for high-volume drilling fluids, ensuring efficient solids separation, improved mud quality, and reliable operation in demanding drilling environments.

Read More

Shale Shaker Optimized for Faster Cuttings Removal

Discover how an optimized shale shaker accelerates cuttings removal, enhances drilling mud performance, and improves overall solids control efficiency in modern drilling operations.

Read More

Reliable Shale Shaker for Oilfield Mud Treatment

Learn how a reliable shale shaker enhances oilfield mud treatment, improves solids control efficiency, and supports stable drilling operations. Discover key features, performance benefits, and why quality shale shakers matter in modern drilling projects.

Read More

Reliable Solids Control Equipment for Improved Mud Performance

Discover how reliable solids control equipment enhances mud performance, reduces downtime, and improves drilling efficiency. Learn about shale shakers, centrifuges, and other key components for optimal drilling fluid management.

Read More

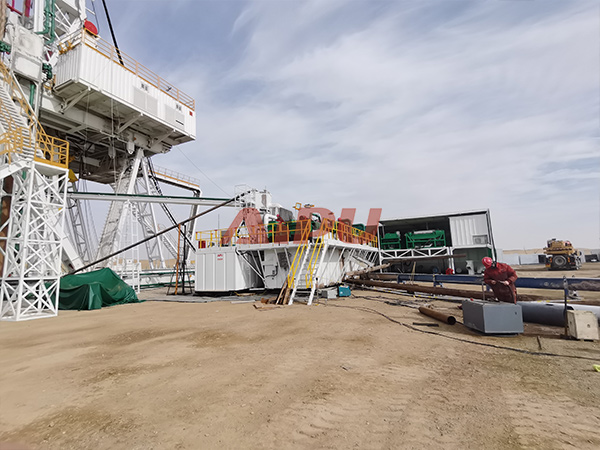

Modern Drilling Rigs Demand Advanced Solids Control Systems

Modern drilling operations require highly efficient, stable, and fully integrated solids control systems to maintain optimal drilling fluid properties and ensure operational safety. As drilling environments grow increasingly complex—encountering deeper fo

Read More

Advanced Solids Control Solutions for Drilling Fluid Recycling

Comprehensive exploration of advanced solids control solutions designed to enhance drilling fluid recycling efficiency, improve mud quality, and reduce operational costs in oilfield drilling.

Read More

High-Performance Solids Control System for Oilfield Mud Treatment

A detailed overview of high-performance solids control systems designed for oilfield mud treatment, ensuring cleaner drilling fluids, reduced costs, and improved drilling efficiency.

Read More

Solids Control System for High-Performance Drilling and Stable Mud Circulation

Learn how an efficient solids control system improves drilling fluid quality, minimizes waste, and supports high-performance drilling across diverse well conditions.

Read More

Advanced Solids Control System for Stable and Efficient Drilling Operations

Explore how a professional solids control system enhances drilling efficiency, improves mud quality, and reduces operational cost across modern drilling projects.

Read More