Latest News & Updates

Stay informed with AiPu's industry insights, product launches and technology advancements

High-Quality Shale Shaker from China: AIPU's Engineering Excellence in Solids Control

The pursuit of high-quality equipment is paramount in drilling operations, where reliability and performance directly impact safety, efficiency, and profitability. Chinese manufacturers have made significant strides in producing shale shakers that meet in

Read More

Why Choose Chinese Shale Shaker Suppliers for Your Drilling Needs: The AIPU Advantage

The global oil and gas industry faces constant pressure to improve drilling efficiency while reducing operational costs. In this challenging landscape, equipment selection becomes critical to success. While numerous shale shaker suppliers exist worldwide,

Read More

Chinese Shale Shaker for Mud Cleaning and Drilling Fluids: AIPU's Comprehensive Solutions

In the complex ecosystem of drilling operations, efficient mud cleaning and drilling fluid management are critical for success. As the primary stage of solids control, shale shakers play a pivotal role in ensuring drilling fluid integrity, equipment prote

Read More

Environmentally Friendly Shale Shaker Solutions from China: AIPU's Green Technology Leading Sus

The global energy industry is increasingly prioritizing environmental stewardship alongside operational efficiency. In drilling operations, shale shakers play a pivotal role in reducing waste, conserving resources, and minimizing ecological impact. AIPU S

Read More

Top Chinese Shale Shaker Manufacturers for Oilfield Drilling: Leading the Global Market with Innovat

The global oilfield drilling industry relies heavily on efficient solids control equipment to ensure operational efficiency, cost-effectiveness, and environmental compliance. Among the key players, Chinese manufacturers have emerged as leaders in producin

Read More

Why Some Clients Require Drilling Mud Agitators Equipped with Electric Control Panel?

In the complex and high-stakes environment of oil and gas drilling, every component on the rig site plays a critical role in ensuring safety, efficiency, and operational success. One such component is the drilling mud agitator, a equipment used to agitate

Read More

Shale Shaker Screen Cleaning Methods: Ensure Efficiency and Extend Service Life

The shale shaker screen is the core separation medium of drilling fluid solid control systems, and its cleanliness directly determines separation efficiency, drilling fluid quality, and operational costs. Clogged or contaminated screens lead to reduced th

Read More

Shale Shaker Benefits in Drilling: Maximizing Efficiency and Reducing Costs

Shale shakers are the cornerstone of modern drilling operations, serving as the first and most critical stage in solids control systems. By efficiently removing drill cuttings and other solids from drilling fluid, they deliver far-reaching benefits that i

Read More

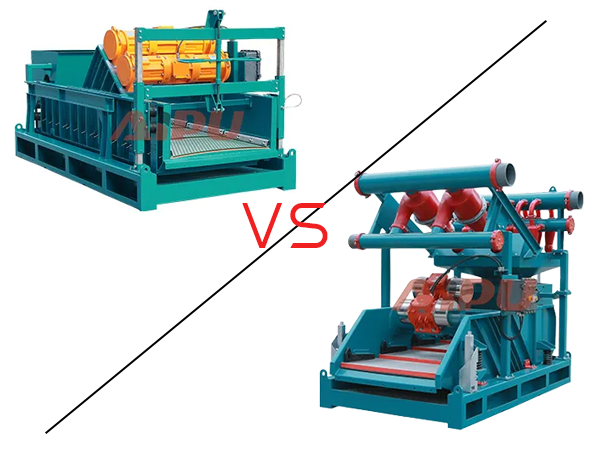

Shale Shaker vs Mud Cleaner: Understanding Their Roles in Drilling Solids Control

In drilling fluid systems, solids control equipment works sequentially to remove impurities and maintain mud quality. The shale shaker and mud cleaner are two critical components in this process, but they serve distinct functions and operate at different

Read More

Strategies for Shale Shaker Efficiency Improvement: Maximizing Performance and Reducing Costs

Efficiency is the cornerstone of effective solids control in drilling operations. As the primary equipment in mud systems, shale shakers directly impact drilling fluid quality, equipment longevity, and operational costs. This article explores actionable s

Read More

The Indispensable Role of Shale Shakers in Drilling Fluid Systems: Foundation of Efficient Solids Co

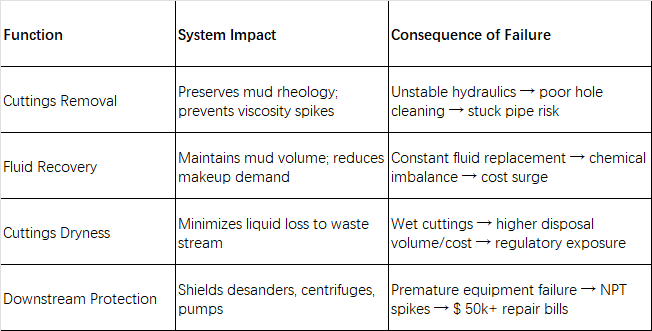

In oil and gas drilling, the drilling fluid system functions as the operational circulatory system—cooling the bit, carrying cuttings, stabilizing the wellbore, and transmitting hydraulic energy. At the very heart of this system lies the shale shaker: the

Read More

What Does a Shale Shaker Do? Core Functions & AIPU’s High-Performance Solutions

In oil and gas drilling operations, the shale shaker serves as the indispensable frontline defense of the solids control system. Positioned immediately after the drill string returns to the surface, it performs one mission with unwavering precision: separ

Read More

AIPU Shale Shakers for Sale: Premium Quality and Unbeatable Value

When seeking a shale shaker for sale, discerning buyers prioritize reliability, efficiency, and long-term value. AIPU Solid Control Co., Ltd. stands as a trusted global manufacturer, offering high-performance shale shakers engineered to excel in diverse d

Read More

Best Shale Shaker Manufacturers: A Complete Guide to Choosing Quality Solids Control Equipment Suppl

The oil and gas drilling industry demands reliable, high-performance solids control equipment, and selecting the right shale shaker manufacturer is one of the most consequential decisions drilling contractors and oilfield...

Read More

Complete Guide to Shale Shaker for Oil Drilling: Everything You Need to Know

The shale shaker for oil drilling represents the most critical first-stage solid control equipment in any drilling fluid recycling system. As the primary solids separation tool on a drilling rig, the shale shaker plays an indispensable role in maintaining

Read More

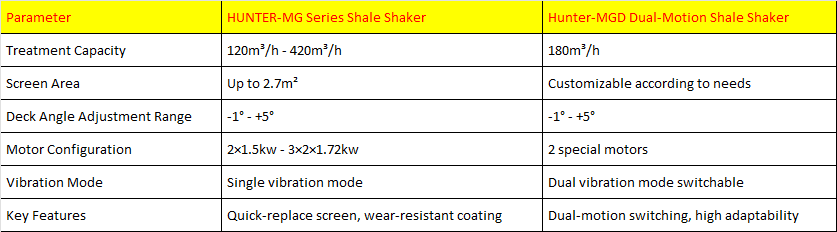

How Do Top Chinese Shale Shakers Enhance Drilling Efficiency and Reduce Operational Costs?

In the oil and gas drilling industry, solids control systems are the core of ensuring efficient and economical operations, and shale shakers, as the first-stage solid-liquid separation equipment in the system, directly determine the subsequent processing

Read More

Shale Shakers: The Definitive Guide to Function, Technology, Types, and Why AIPU Solid Control Domin

In modern oil and gas drilling, the shale shaker stands as the indispensable cornerstone of solids control systems. Positioned at the very front of the mud circulation loop, this engineered marvel performs the vital task of separating drill cuttings from

Read More

The Core Role of Solids Control System in Oil Drilling

A solids control system is an indispensable and critical component of modern oil drilling operations, directly impacting drilling efficiency, cost control, and environmental protection. During the drilling process

Read More

Mud Cleaner: A Key Component in Drilling Waste Management

In the drilling industry, managing the vast quantities of generated waste is a critical operational and environmental challenge. The mud cleaner plays a vital role in this process, serving as a specialized solid control equipment positioned downstream of

Read More

What is a Mud Cleaner? The Essential Component in Drilling Fluids Solids Control

In the complex ecosystem of drilling operations, maintaining the properties of drilling fluid (mud) is paramount. Efficient solids control is the backbone of this process, and a key player in this system is the mud cleaner. This article provides a compreh

Read More

Mud Cleaner Working Principle: Technical Deep Dive into Hydrocyclone Separation Technology

The mud cleaner represents one of the most sophisticated solid control devices in modern drilling operations, combining the principles of centrifugal separation with fine mesh screening to achieve superior solids removal efficiency. This technical analysi

Read More

The Mud Cleaner: Technical Deep Dive into Configuration, Efficiency, and Optimal Operation

Beyond its basic definition, the true value of a mud cleaner in a drilling system is unlocked through a detailed understanding of its technical configurations, efficiency metrics, and operational best practices. This article provides a technical deep dive

Read More

mud cleaner screening and desanding process

The mud cleaner's screening and desanding process represents a tandem separation technique where centrifugal desanding and fine-mesh screening operate sequentially on a single unit to achieve superior solids control and fluid recovery.

Read More

mud cleaner with hydrocyclones and shaker

The mud cleaner is fundamentally defined by its integration of hydrocyclones and a fine-mesh vibrating shaker into a single, purpose-built machine. This hybrid design creates a highly efficient two-stage separation process specifically engineered to solve

Read More

compact mud cleaner for drilling rigs

Compact mud cleaners represent a specialized engineering solution designed to deliver high-efficiency solids control within the stringent space and weight constraints of modern drilling rigs, particularly offshore platforms, mobile land rigs, and remote o

Read More